天游ty8官方网站

MES introduction

As today's manufacturing companies face increased customer manufacturing quality requirements, they need to have a traceability system for faster delivery and personalized customization. Companies must constantly improve their productivity, complete production with less energy and resources, be able to cope with increasing cost pressures, and ultimately remain competitive in increasingly fierce market competition.

The MES developed by Suzhou Yunzao Intelligent Technology Co., Ltd. is precisely in the face of increasingly fierce market competition, accurately responding to increasing customer requirements, achieving high quality management, helping to improve production efficiency and shorten product delivery. Time, improve product quality and reduce production costs, so that enterprises continue to enhance market competitiveness.

The MES system of Suzhou Yunzao Intelligent Technology Co., Ltd. is based on the needs of flexible manufacturing in the factory, and optimizes the entire production process from order to product completion. When real-time events occur in the factory, they can respond to them in a timely manner, report them, and guide and process them with current accurate data. This rapid response to changes in state can reduce the company's internal value-free activities and effectively guide the plant's production operations, so that it can improve the factory's timely delivery capacity, improve the material's circulation performance, and thus improve the return on production. .

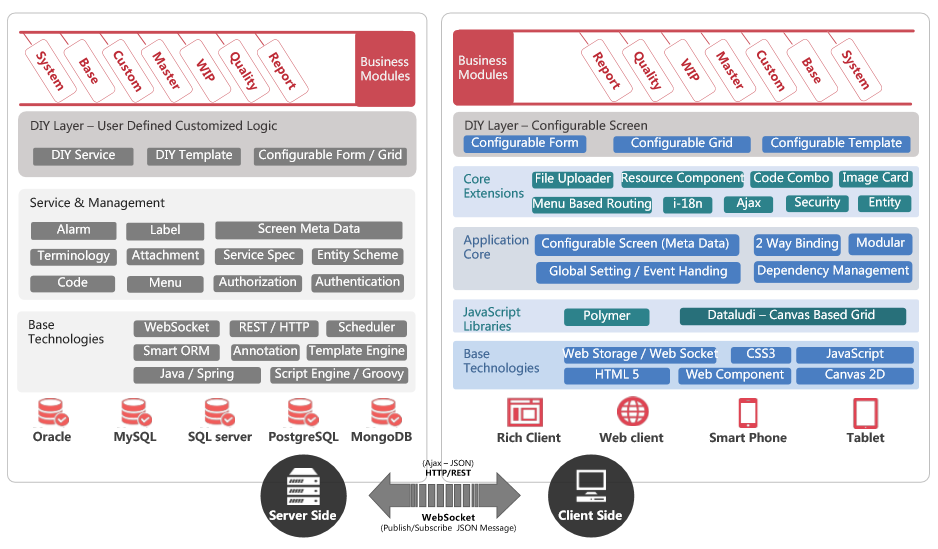

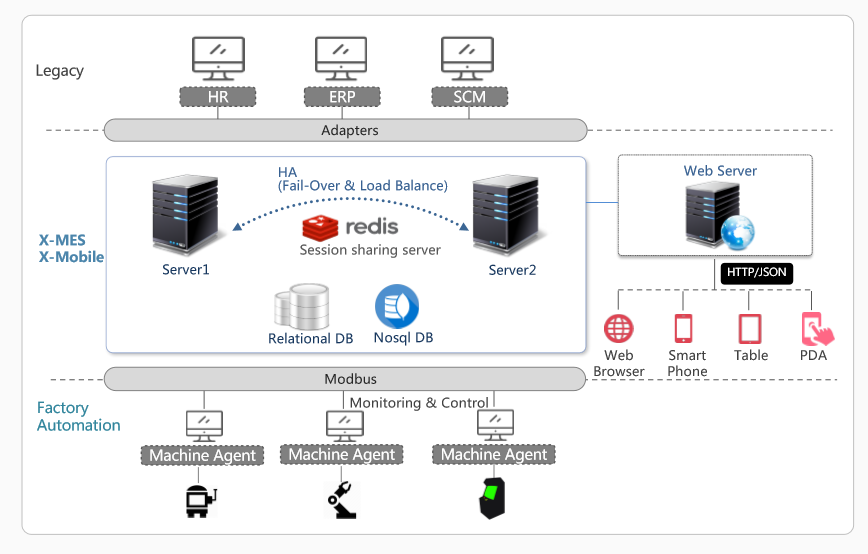

Product software architecture

Software Architecture

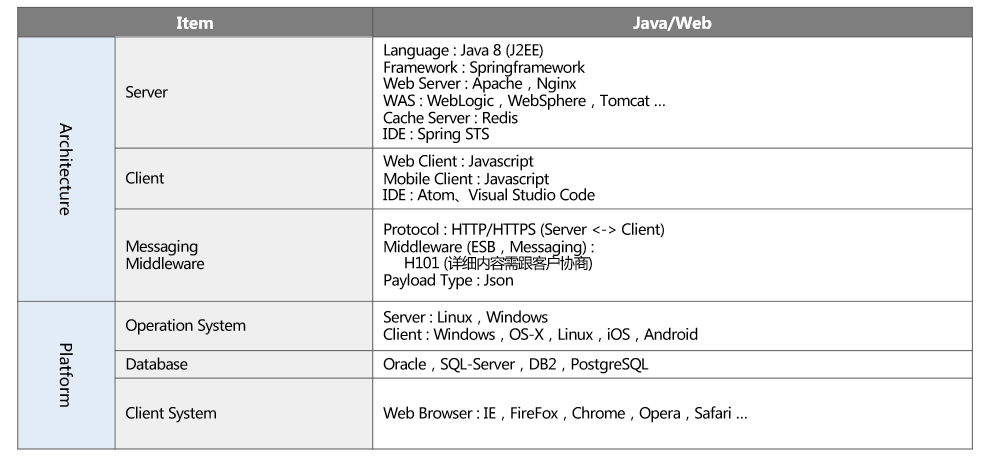

Development Platform

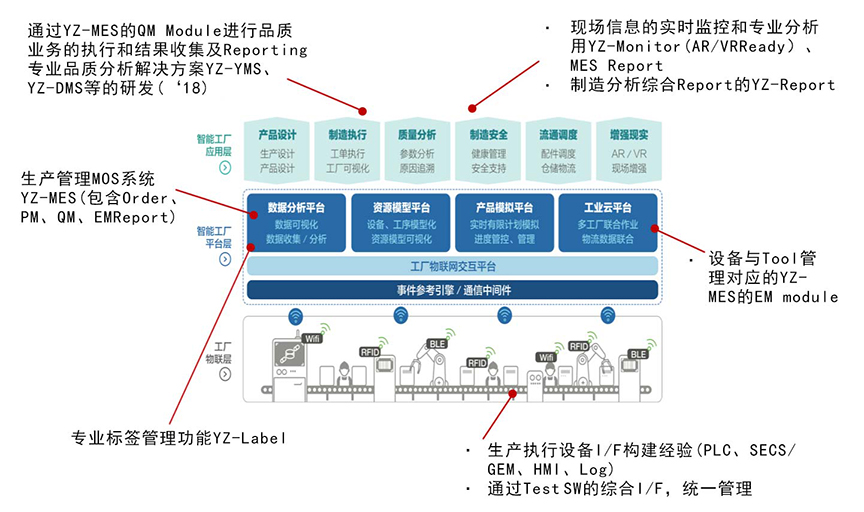

MES smart factory application

Hardware architecture

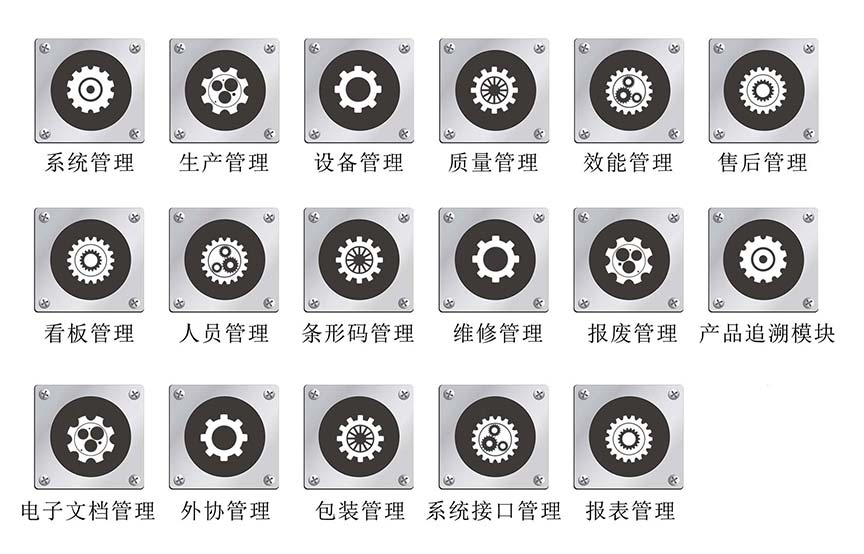

functional module

MES features

1. Improve the formulation and adjustment of production plans: Improve the efficiency and accuracy of the production planning of the enterprise through the production planning management module of MES

2. Improve equipment management status: Through the MES equipment management module, a clear online electronic account can be established for all equipment of the enterprise, and the location and equipment of the equipment are recorded.

Status, periodic inspection of equipment, overhaul, etc.

3. Product production cycle tracking: Through the quality control module of MES, establish a separate quality tracking record for each processed product, and all the quality control related to the product.

The data is stored centrally in the MES system and can be viewed at any time through the query.

4. Data real-time monitoring: Through the quality control module in the MES system, a separate quality tracking record is established for none of the processed products, and all the qualities related to the product are

The quantity control data is stored centrally in the MES system and can be viewed at any time through the query.

MES product advantages

1. Accurate production logistics management: The logistics situation at the production site is changing every minute and every minute, and it needs real-time, simple and fast operation mode support.

2. Effective production resource management: By quickly and correctly understanding the production resources, the utilization rate of production resources can be more effectively guaranteed and improved.

3. Perfect quality and product traceability service: trace the root cause of quality problems, provide basic data for analysis, and recover in time to reduce greater losses.

4. Quickly respond to the ever-changing market: In order to provide better service, less verbal and paper delivery errors, tools that can communicate directly with the site are required.

5. Real-time monitoring at the production site: real-time monitoring of product defects, production schedule, quality, inventory, rapid decision-making and delivery.

6. Professional production management and automation system: With the integration of two technologies and the arrival of smart factories, the production system needs to be integrated with multiple platforms, clients and equipment.

Business feature display

1. Integrate multi-industry best practices

2. Visualization plan assisted scheduling

3. Integrated Work Order Resources

4. Configurable data collection items

5. One-click traceability of the production process

6. Real-time production progress tracking

Technical characteristics display

1. Excel-style form operation

2. Drag and drop grouping summary

3. Rapid development support